Finite Element Analysis

- Mikecon Cenit

- Mar 4, 2019

- 1 min read

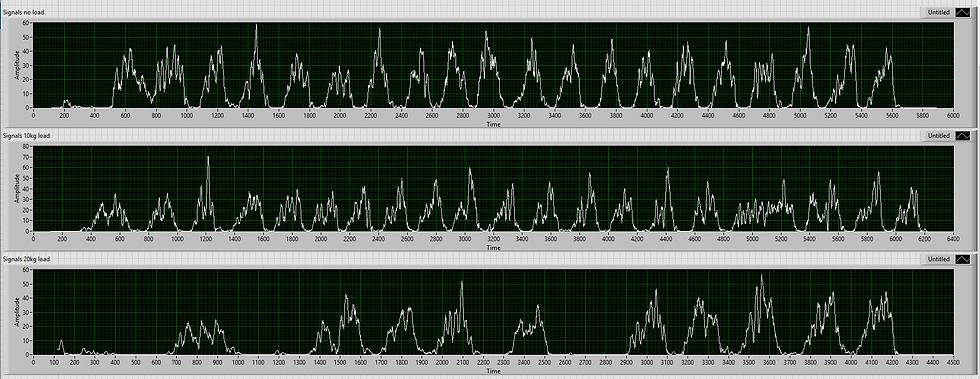

Testing the ratchet gear with FEA simulation

The material used for the developing the ratchet gear is the aluminium 1060-H14 agrade alloy. The alluminium alloy is used as the main body material on the production of the exoskeleton as it is widely acknowledged for its excellent corrosion resistance, high, ductility and highly reflective blue/silver appearance. The 1060-H14 aluminium alloy has a sheer modulus of 2.63+010 N/m^2. The force applied on Finite Element Analysis (FEA) simulation of the ratchet gear is set on 607.6 N. The average human weight is 62 kg = 607.6 N. To make sure the system can handle the force of the spring enough to carry the weight of the average human body plus excess force for the overweight users. The FEA simulation shows the highest 8.850e+007 von Mises of the ratchet gear, way below the sheer modulus of the 1060-H14 aluminium alloy shown on image above.

Comments